With their power and precision, stationary tools increase the versatility and efficiency of a shop, but they also carry hefty price tags. Before buying any, consider the amount and kind of work you do as well as the available floor space in your shop.

Tool Selection: Most shop work with power tools involves cutting wood. Drilling, joining, smoothing, and finishing compose most of the remaining tasks. If this is your situation, you can make a table saw or a radial-arm saw the centerpiece of your shop.

Although the table saw (below) is the preferred tool for cutting plywood panels and making precise joinery cuts, the radial-arm saw is more versatile—it can sand and plane wood as well as cut it. The radial-arm saw is also easier to set up for making repetitive cuts, If your projects entail curved cuts, a band saw is essential. Hobbyists may prefer a scroll saw; its fine blade can cut intricate shapes in lightweight materials. A drill press is a valuable addition; it not only bores holes accurately, but doubles as a sander and a mortiser. A jointer and a planer will enable you to smooth rough-cut boards. If you want to turn wood, as in bowl making or spindle work, you’ll need a lathe.

Budgeting: If your shop space is limited, consider a compact multipurpose shop tool that combines the functions of several individual machines. Although expensive, it may cost less than the total price of the tools it replaces; however, setting it up for different functions can be time-consuming.

If your budget is tight, choose the most versatile tools, such as the radial-arm saw and the drill press, and add accessories as needed. Or, purchase secondhand tools—provided you try them out first.

THE TABLE SAW

Sizing up a table saw: This tool provides a flat,

stationary surface on which materials can be accurately guided over a rotating

circular blade that projects through a slot in the table top. It can execute

a wide range of cuts, including rips, crosscuts, miters, and compound angles.

Most table saws accommodate a 10-inch blade that can be raised or lowered

to adjust the cutting depth, or tilted to cut a bevel. Look for a table

wide enough for the rip fence to be set at least 24 inches from the blade;

add-on table extensions are usually available to support extra-large work.

A 1½- to 3-horsepower motor with a speed of 3450 rpm is adequate for home-workshop use.

Vital to the table saw are its safety features: a plastic or metal blade guard, a splitting device to keep the wood from binding on the blade, and anti-kickback fingers.

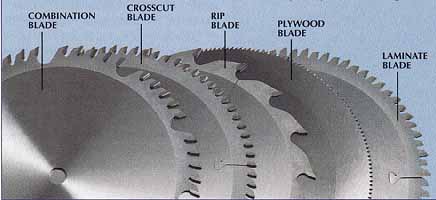

== Table saw Blades and Accessories ==

To make the most of a table saw, outfit it with a lull complement

of blades and special cut ting tools. The blade sold with most saws is

a combination blade designed to work efficiently on both crosscuts—across

the wood grain—or on rip cuts—along the wood grain, although specialized

blades for each of these cuts are available. For cleaner edges and a narrower

kerf, use a hollow-ground blade; its teeth are set directly in line with

the body of the blade, which is thinner than its cutting edge. Plywood

and laminate blades, de signed for these materials, make smooth cuts with

less splintering or damage to the layers.

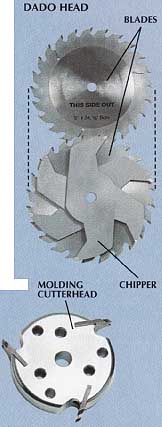

For cutting rabbets and dadoes—the rectangular channels employed in

woodworking joints—the saw takes a dado head, which consists of two circular

blades assembled around a variable number of inner blades called chippers.

The chippers cut away wood between the two main blades. On quality dado

heads the main blades are hollow ground. For more intricate cuts, a molding

cutterhead is used as a mount for three identically contoured blades that

are fastened into it with screws. Except for hollow-ground blades, all

these can be purchased with carbide tips. Though more expensive, they stay

sharper much longer.

COMBINATION BLADE; CROSSCUT BLADE; PLYWOOD BLADE; LAMINATE BLADE; DADO HEAD

Accommodating a table saw. For rip cutting, you need

adequate space both in front of and behind the table for the full length

of the board. To support the cut sections as they come through the saw,

you can clamp a roller assembly to a sawhorse, or buy or make a roller

stand. For crosscutting, make room on each side of the table to accommodate

the workpiece.

A VERSATILE ALTERNATIVE: THE RADIAL-ARM SAW

Except when executing rip cuts, the blade of a radial-arm saw moves while the wood remains stationary. The blade, held in a yoke, rides along a track, tilts 90 degrees right or left, and swivels

360 degrees beneath a support arm that is adjustable both laterally and vertically. These capabilities give the saw much of the mobility and flexibility of a portable power saw; however, all these variables can make the radial arm saw difficult to adjust with precision.

A typical radial-arm saw for the home workshop has a blade 10 inches in diameter. It cuts to a maximum depth of 3 inches, crosscuts boards 13 inches wide, and rips wood up to 244 inches wide. Look for a saw with a heavy- duty arm-and-support-post assembly and a motor rating of at least 2 horsepower. An automatic or manual brake is also important. Other desirable features are floating blade guards and adjustable anti-kickback fingers for protection during ripping.

The radial-arm saw accepts the same types of blades as a table saw, including dado blades, but because the blade rotates toward the workpiece in most operations, the saw may "feed” through the wood. To prevent this, use only blades whose teeth have a maximum hook angle of 5 degrees, as labeled on the package.

By removing the standard circular blade and tilting the saw’s motor in its yoke, you can fit the tool with a number of accessories. A drum sander lets you use the saw’s spinning action to smooth wood edges (right); clamp on an auxiliary table cut from plywood and notched to provide a raised surface for the workpiece so the drum contacts its entire edge. Molding cutterheads can be used, but the saw will need a special blade guard. A sanding disk can be added (photograph, left); and for certain planing tasks, such as cutting wide bevels on the surface of a raised panel, the radial-arm saw can be fitted with a circular planing attachment (photograph).

Unlike a table saw, the radial-arm saw can be backed against a workshop wall. In rip cutting, the blade is set sideways; in crosscutting (right), the lumber is lined up against the fence at the back of the table and the yoke is pulled forward along its arm to make the cut, then returned behind the fence. The machine itself occupies roughly 6 square feet and requires a few feet of maneuvering space in front for its operator; however, you will also need sufficient space on both sides — ideally 10 to 12 feet — to accommodate long pieces of lumber. Worktables on either side of the saw are useful for supporting long boards.

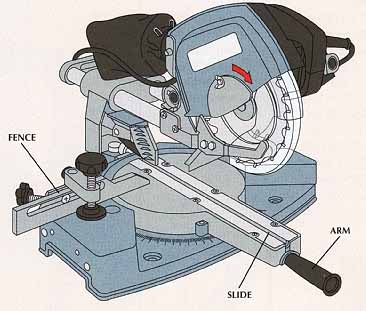

== The Sliding Compound-Miter Saw

This tool is ideal for making precision miter, bevel, and compound cuts.

Since the arm and table rotate as a unit, setting accurate angles is easy.

The tool can crosscut and bevel stock up to 12 inches wide, and make miter

and com pound cuts in stock up to 8 inches wide. It features an 84-inch

blade that runs along a slide, and an electric brake to stop the blade

spinning quickly when the trigger is released.

==

SAWS THAT CUT CURVES

The band saw.

Prized for its ability to cut curved lines and for its unmatched depth of cut, a band saw has a continuous blade driven in one direction around two wheels, one above the other, encased in a metal housing. Only the section of blade above the worktable is exposed. Because the blade pulls the workpiece toward the table, kickback cannot occur. The size of a band saw is determined by its throat, the distance between the blade and the vertical arm at the tool’s back; its capacity is rated by maximum depth of cut. An average home tool has a throat of 10 to 14 inches and will cut through wood 6 inches thick. Most home band saws have 4- to-1 -horsepower motors and take blades from 4 to 4 inch wide with a variety of teeth configurations for different materials and types of cut.

Look for a band saw table that tilts to 45 degrees so you can make bevel cuts. Guide bars for a rip fence and a miter gauge will allow you to rip boards and make a range of cross-grain cuts.

Band saws do not take up much space, but you will need enough room to maneuver materials.

Sometimes called a jig saw, the scroll saw can make intricate cuts in thin material. The slender blades are held between two chucks on either side of the table. For the home shop, this type of saw needs a cutting depth of about 2 inches. Throat depth ranges from 13 to 30 inches. Scroll-saw motors are generally rated at 4 horsepower; look for one that has at least two speeds. Other useful features are a tilting table, built-in lights, spring- loaded guards that hold the work against the table, and blowers that keep the cutting area clear of sawdust.

The blades are avail able with different tooth configurations and thicknesses that enable you to cut diverse materials like wood, plastic, and soft metals; spiral blades are designed for cutting tight curves (photograph: WOOD AND PLASTIC CUTTING BLADE; SPIRAL CURVE-CUTTING BLADE; METAL-CUTTING BLADE).

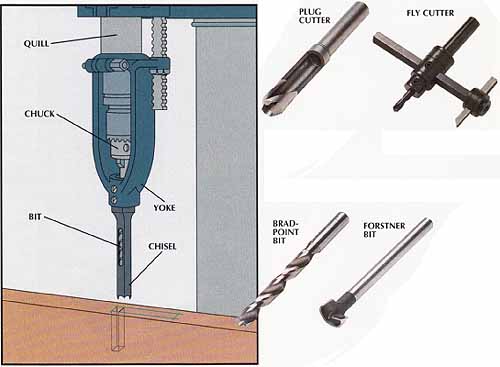

THE DRILL PRESS

Sizing it up.

A drill press cuts perfect circular openings as much as 6 inches in diameter; with accessories (below), it can do much more. Drill-press capacity is determined by the distance from the column to the center of the spindle—typically 7 inches. The table slides up and down the column to adjust the distance between the tabletop and the chuck.

The spindle of the press is covered by a metal sleeve known as a quill. The quill is lowered by means of a feed lever to drill holes of varying depth, the maximum depth depending on the distance the quill travels. Quill travel ranges from 2 to 4 inches for home workshop models. An adjustable depth stop limits the quill’s extension. Select a drill press that has spring action to return the quill to the starting point. Motor sizes vary from - to horsepower, but the real key to a drill’s versatility is its range of speeds. Most drill presses have five to six speeds that are adjusted by a step-pulley system.

A mortising attachment, with a yoke that clamps on the drill- press quill (left), creates crisp, clean mortises. The yoke holds a square, hollow chisel that forms the corners of the mortise, while the auger-like bit inside does the bulk of the cutting. In addition to common bits such as a twist bit, a spade bit, and a hole saw, a number of specialized bits are avail able (photographs). A brad-point bit has a center point to guide the drill; the sharp spurs along the outside prevent tear-out. A Forstner bit makes clean-edged, flat-bottomed holes up to 1 inch in diameter, but it is guided by its edges rather than its point, making it ideal for creating angled holes. A plug cutter produces wood plugs for concealing screw holes, and can also make short dowels. Fly cutters can make holes up to 8 inches in diameter.

MACHINES THAT SHAPE WOOD

Jointers are used to shave small amounts of wood from the edges and faces of boards, yielding smooth, even surfaces. The jointer can also cut rabbets and tenons for woodworking joints, and shape bevels and tapers. Jointers suited to home workshops have 6-inch- wide blades capable of cuts up to inch deep. Look for one with a table at least 27 inches long and a motor rated - horsepower or higher. A fence that tilts in both directions is very handy. A spring-loaded guard covering the blades, which is moved aside as the workpiece is pushed through, is an essential safety feature.

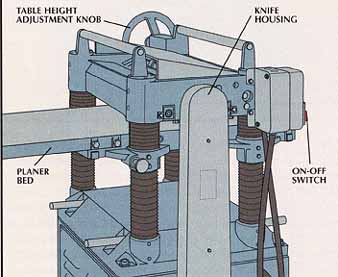

Planers.

For reducing the thickness of boards uniformly or smoothing rough lumber and glued-up panels, the planer is ideal. The machine’s planer bed moves up or down to accommodate the thickness of the board. An infeed roller pushes the board into the cutterhead mounted above the bed, and an outfeed roller moves the wood out of the ma chine. Although the tool will produce a smooth surface that is parallel with the opposite face, it cannot straighten a warped board.

For home use, look for a planer that can handle boards up to 12 inches wide. A cast-iron planer bed and a three-blade cutterhead are desirable features.

== A Table for Stationary Routing ==

Supporting a router upside down with its bit protruding from a hole,

a router table transforms this portable tool into a stationary one. Among

the tasks you can accomplish on a router table are shaping edges, plowing

dadoes, and cutting woodworking joints. Look for a table with a flat top,

an adjustable fence, and a miter gauge slot—or build your own.

THE LATHE

Unlike most shaping tools, which turn a blade, a lathe turns the wood, and the wood—known as a blank— is scraped and sheared by hand-held chisels and gouges steadied against a tool rest. For spindle turnings such as chair legs or balustrades, the wood is held between centers in the headstock and tailstock. For bowl making, work is mounted on the headstock alone. A typical home workshop lathe has a capacity of 36 inches between centers, and is powered by a 1/2- to 3/4-horsepower motor. For a machine that will not vibrate, look for a lathe with cast-iron head-stocks and tailstocks. A basic set of lathe tools (photograph: square-end scraper; roughing-out gouge; spindle gouge; skew chisel; parting tool; round-nose scraper) will be sufficient to get you started.

A POWERFUL SANDER

The belt-disk sander.

This tool combines a stationary disk sander with a belt sander. The disk sander, a rotating plate of steel or aluminum faced with abrasive sanding paper ranging in width from 8 to 12 inches, is most useful for smoothing end grain, miter cuts, and curved edges. The work is supported on the table in front of the disk. Buy a model with a tilting table to facilitate sanding angled surfaces, and with a slot for a miter gauge. The belt sander runs a continuous abrasive belt around two drums. Positioned horizontally, the belt is used for sanding surfaces and lengthwise edges; for such operations, the stock rests on the belt, one of its edges braced against the stop fence. The belt can also be positioned vertically for smoothing end grain. Common belt sizes are 4-by-36 and 6-by-48 inches. A 1/2- to 3/4-horsepower motor is adequate for the home shop.

THE BENCH GRINDER

This relatively inexpensive tool is primarily used for sharpening the blades of other shop tools. But it is also helpful for such jobs as grinding off rivets or smoothing welded joints. The model most practical for home workshop use has a fully encased 1/4- to 1/2-horsepower motor and two aluminum-oxide grinding wheels fit ted with covers and clear-plastic eye shields.

Home-workshop bench grinders generally have wheels ranging in diameter from 6 to 8 inches. A tool equipped with medium-coarse and medium-fine wheels is versatile enough to handle most tasks. To sharpen chisels, plane irons, and maintain other woodworking tools, add a finer 80x or 120x wheel (photograph, left); a cloth buffing wheel (photograph, right) polishes the tool’s beveled edge. An adjustable tool rest is an essential feature for this task.

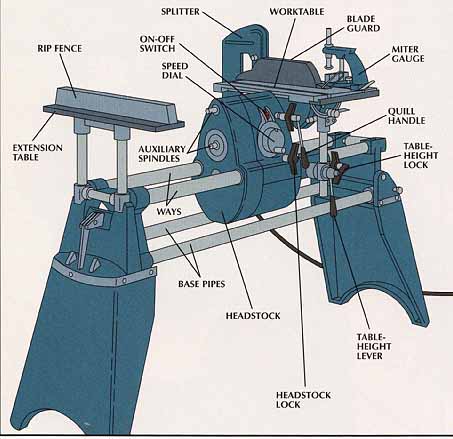

A WORKSHOP IN A SINGLE TOOL

Evaluating a multipurpose tool.

An alternative to a roomful of specialized machines, a well-engineered multipurpose power tool typically occupies only 12 square feet (left). Powered by a 2-horsepower variable- speed motor, and with auxiliary spindles and adjustable tubular-steel frame, this machine incorporates the capacities of five separate tools: a 10-inch table saw, a 12-inch disk sander, a 164-inch drill press, a 34-inch lathe, and a horizontal boring machine. With appropriate accessories, it can be further adapted for use as a band saw, saber saw, jointer, and belt sander.

Changing the tool’s function involves shifting the position of the headstock and spindle, installing the proper bit, blade, or disk, and assembling the appropriate work-support jigs. The ways are also movable; normally locked horizontally, they can be tilted upright for vertical work.

For sawing a wide panel (left), the headstock is shifted along the ways to position the circular blade; the miter gauge is removed; and both worktable and extension table are set in place to support the wood. (The supports for the panel behind the machine have been omitted here for the sake of clarity.) The rip fence guides the edge of the panel as the cut is being made, and the splitter behind the blade guard keeps the cut from binding on the blade.

When the tool is used as a lathe (right), the headstock is adjusted later ally along the ways to accommodate the length of the wood being turned. Lathe centers are attached to the drive shaft and to a tailstock attachment that locks in place at one end of the frame. The worktable and extension table are removed, and the same carriage that supports the worktable holds the tool rest to steady the chisel.

For use as a drill press (left), the ways are tilted upright and locked in position. Both headstock and worktable are raised or lowered along these tubes to accommodate the size of the piece being drilled; the worktable also tilts to support the workpiece at any angle. As with a conventional drill press, the quill is lowered by means of a feed lever.

Next: Power-Tool

Safety

Prev: Introduction and Equipping

the Shop with Portable Tools