This section and the next are the two most important sections in this guide, with regard to the mechanical care of your car. Read them carefully, because if you grasp the theory and follow the recommendations, your car engine will stand an excellent chance of performing reliably without the need for repair for many years.

THEORY OF LUBRICATION

Engine friction caused by the sliding of pistons against cylinder walls, the rotation of journals in bearings, and the relative movement of many different engine parts one to another is responsible for producing wear and generating some of the heat in your car engine. Friction caused by metal contact between the various surfaces in your car engine can be drastically reduced by the presence of a lubricant, commonly engine oil.

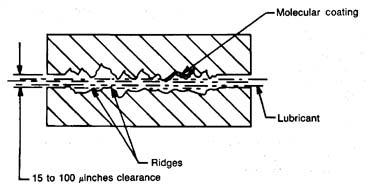

The lubricant does its job remarkably well, so long as it is kept clean and doesn’t get too hot. Engine lubricants actually function to separate two surfaces in relative motion and so reduce metal contact. They perform this task by filling minute depressions in metal that are caused by the machining process used to manufacture the parts. In addition, the lubricant “plates” all the ridges caused by machining with a thin layer of oil molecules, or in some oils, an oil additive (Fig. 1).

Fig. 1 Oil molecules coating metallic surfaces.

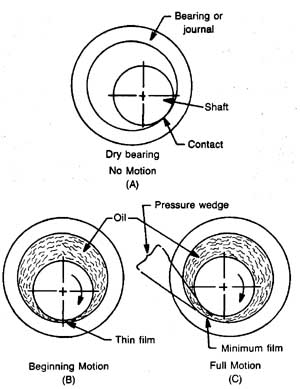

There are many different parts in your car that require lubrication. The crankshaft, for example, is one of the more important of these. The part of the crankshaft (or any other shaft, such as a camshaft) that rides in a bearing is called a journal (Fig. 2). When the shaft is not moving (engine off), its weight allows the journal to contact the bearing as in (A). When the shaft starts to turn (engine start up), the journal rolls on the thin film or coating of oil mentioned above as in (B)). As the shaft turns further (engine running), oil is pulled into a wedge-shaped opening between the journal and the bearing, and the oil pressure increases. Eventually, the pressure moves the journal away from the wall of the bearing, as in (C).

Fig. 2. Journal and shaft lubrication.

Lubrication, then, is the process that modifies the frictional characteristics and reduces wear at the surface interface between two or more parts when in motion. A lubricant (engine oil in this case) is the medium introduced between such parts to accomplish this.

VISCOSITY

You might ask what keeps the oil from being easily washed or squeezed out of the space between the surfaces of the parts when they are in relative motion. The answer is viscosity. Viscosity is the property of a liquid that governs how it flows at various temperatures and pressures. At room temperature, water pours or flows from a cup more easily than molasses. Therefore, the molasses is thicker or more viscous than the water. The viscosity of most liquids is dependent upon temperature. In our example, if you heat the molasses, it will gradually pour more quickly from the cup. The viscosity of the molasses changes with temperature; it becomes less viscous as it is heated.

In the winter, when the temperature of your car engine is low, oil viscosity must be low (oil must be thin) for ease of starting. If the oil is thick, you might have a hard time starting your car in the winter and eventually run down the battery.

When the engine warms up, the oil tends to become less thick because of the heat. But when your engine is hot, it needs thicker oil to provide for adequate lubricant film between the surfaces of its running parts. In other words, just the opposite of what nature intended for most fluids. Engine oils must be thin at low temperatures and thick at high temperatures. This dilemma is solved by introducing additives to oil. Oils with additives that modify their natural tendency to thin as the temperatures rises are called multi-viscosity oils. Our first recommendation is to use a quality multi-viscosity or multi-grade oil in your car engine for protection at all driving temperatures.

The Society of Automotive Engineers (SAE) classifies engine oils in two general groupings: viscosity and performance (Table 3-1).

Table 3-1. Oil Viscosity and Performance.

VISCOSITY |

PERFORMANCE |

1. SAE 5W, 10W, 20W, 25W measured at 0°F 2. SAE 20, 30, 40, 50 measured at 210°F 3. Multi-grade—those that have viscosity characteristics meeting requirements at both 0°F & 210°F |

1. SC, SD, SE, SF—oils for general engine service (see note) 2. CC, CD—diesel engine and heavy, dirty gasoline engine service |

NOTE:

SC oil—meets 1964 to 1967 requirements of auto manufacturers

SD oil—meets 1968 to 1971 requirements of auto manufacturers

SE oil—meets 1972 to 1979 requirements of auto manufacturers

SF oil—meets 1980 to 1986 requirements of auto manufacturers

Always use an oil with the minimum rating for performance as specified for your car year. You may upgrade. For example, you can use SF grade oil for any of the model years shown. SF grades, by the way, were specially formulated for emission-controlled engines.

Correct oil viscosity is important to engine performance. If the viscosity is too high, the engine will need to work harder to pump the oil and move it around to the different engine parts to be lubricated. This results in reduced engine power, and fuel consumption is increased as much as 15 percent. If the viscosity is too low, sealing between the piston rings and cylinder will be poor. The increased blowing of oil past the rings and into the combustion chamber therefore increases oil consumption. To get the best all-around performance use a 10-W30 or 10-W40 oil.

Although a 10-W30 oil satisfies precisely only the 10W and 30 specifications, it can also serve as a 20 oil, since in operating between 10W to 30 it passes the 20 characteristic line. The same is true of the 10-W40 oil.

MORE ABOUT OIL

Lubricating oil is made up of a base oil and additives. Together these must reduce wear, remove heat caused by friction and fuel burning, and prevent accumulation of deposits in the engine. The base oil is usually a mineral oil, sometimes it is synthetic. Additives provide additional performance characteristics that the mineral oil alone does not have. Let’s discuss base oils first.

Mineral or petroleum oils are used as the base oil in engine lubricating oils because of their moderate cost and suitability with the many materials that make up the engine parts. They are refined from various crude oils of which there are three main types:

Paraffin-based or Pennsylvania crude, naphthene-based or Texas crude, and those that are a mix of both. Years ago a paraffin-based oil would have been the best choice for use in your engine, because the naphthene-based oils contained a lot of asphalt which, if not removed, can damage your engine. Modern refining methods successfully remove asphalt to a degree that a naphthene-based oil is entirely satisfactory for use. We, therefore, do not recommend any specific oil; just stick with a national brand.

Synthetic lubricants are sometimes used as a base oil. These lubricants are man made organic chemicals. They were originally developed by the aircraft industry to serve the high speed and operating temperatures of jet aircraft engines. Normally, they are used only in specialty applications such as instruments, hydraulic systems, and in heat transfer systems. Their disadvantage in auto engine use is their high cost. However, it is claimed that these lubricants stay cleaner longer and, therefore, engine oil changes are less frequent. You can use them if you like, but their benefits are still being tested, so it’s probably best to stick with natural oils.

Base oils are only half the story on engine lubricating oils. During the refining process certain compounds are removed that are highly effective as lubrication. Also, the properties of mineral oil are not sufficiently strong to stand up to the conditions in a high- performance engine. For these reasons, mineral oils are doctored by the addition of chemicals that will allow the oil to do its job. The only additive we will discuss in detail is the detergent-dispersant additive. For a listing and brief explanation of the more common additives, see Table 3-2. All the better national brands of engine oil contain these and other additives.

Table 3-2. Engine Oil Additives.

Additive Type |

Reason for Use |

Effect |

Detergent-Dispersant Viscosity index improver* Oxidation inhibitor Corrosion inhibitor |

Maintains engine cleanliness Lowers the rate of change of viscosity with temperature Retards oxidative decomposition of the oil Prevents attack of corrosive oil contaminants on bearing and other engine parts |

Keeps oil-soluble material in suspension Stabilizes abrupt viscosity changes Reduces varnish, sludge, and corrosion Reduces wear, increases engine life |

Metal deactivator Anti-wear extreme pressure (EP), and oiliness film strength agents Rust inhibitor |

Passivates metal surfaces Reduces friction Prevents rusting of ferrous engine parts |

Inhibits oxidation of engine parts Prevents scoring and seizure. Reduces wear Protects during storage and from acidic moisture during cold engine operation |

Pour point depressant * Foam inhibitor |

Lowers pour point of lubricant Prevents formation of foam |

Reduces effects of wax in the oil when starting a cold engine. Reduces wear at startup Prevents air entrainment in the oil, which results in adverse effects on oil pressure and heat transfer. |

*A measure of the rate of change of viscosity with temperature. In general, oil having a high viscosity index (VI) has a better temperature-viscosity relationship than oil with a low VI; better meaning the rate of change of viscosity with temperature is less.

**The pour point of an oil is determined by lowering the temperature of the oil in a test jar until no movement of the oil (within 5 seconds) occurs when the test jar is moved from a vertical to a horizontal position. The pour point of an oil is Important only for low engine temperature operation.

It is important to know about detergent-dispersant additives because engine oils are available as both detergent and non-detergent types. Thus, as a consumer you have a choice to make. Let’s discuss exactly how this type of additive works.

As far as is known, the detergent-dispersant additives commonly used in engine oils chemically unite with the compounds in the oil that tend to form sludge and varnish. This chemical action prevents deposits and removes built-up deposits. Also, by this chemical action, the deposits are neutralized and do not cling to surfaces. The deposits are kept dispersed or suspended in the oil and are eventually removed in part through action of the engine oil filter.

Varnish is a hard, lustrous, oil-insoluble deposit that forms on the piston. It must be removed by a solvent. It is formed by oxidation of hydrocarbons in oil exposed to high temperatures. The highest temperature the engine oil experiences is at the piston skirt, hence, the formation of varnish there. The same materials that form varnish can coagulate with carbon, oil, water, and dirt in the crankcase to form sludge. Sludge is a black mud that can be removed by wiping. The presence of water in the crankcase is the major cause of sludge formation.

Water collects in the crankcase in two ways. Because it is a product of fuel combustion, the hydrogen in the fuel combines with the oxygen in the air to form water. Most of this water is exhausted as a vapor with other hot gases in the exhaust. Some condensation does occur as the engine cools, and this condensed water can leak past the piston rings into the crankcase. Another way water finds its way to the crankcase, and hence the engine oil, is from the crankcase ventilating system. When the engine is cold, moisture in the air drawn through the crankcase by the ventilating system may condense on cold engine parts and leak into the crankcase. This problem has been significantly reduced with the newer closed crankcase ventilation systems and the recirculation of exhaust gases that quickly warm the engine.

The deposits formed by chemical action of the detergent-dispersant additive show up in the oil as black particles. Because these black particles are carried in the oil, the color of the oil will be dark brown or even black. A non-detergent oil would not exhibit this coloration. So, don’t be alarmed by the dirty color of the detergent oil—this proves that the oil is doing its job. A non-detergent oil will not prevent sludge and varnish formation. The oil will look a beautiful golden yellow because the sludge and varnish are left in the engine where they cause wear and foul oil passages. Our recommendation is to always use detergent-type oil.

As the detergent-dispersant additive continues to chemically unite with sludge and varnish-forming compounds in the oil, it will eventually be used up. Once this occurs, the oil will rapidly become polluted. Tests have shown that once the detergent-dispersant additive is 50% consumed, the remaining detergent-dispersant additive is of insufficient concentration to remove sludge and varnish from the engine. In most cars the detergent dispersant additive reaches the 50% strength level after approximately 2,000 to 3,000 miles of operation. This eventually occurs with any type of additive, so changing the oil is very important. Based on this, we recommend changing the oil every 3,000 miles or sooner. This might seem too frequent, but for the average driver, it is only three to four times a year. This is probably the most important recommendation in this guide.

Be cautious in changing from a non-detergent to a detergent oil. If you have been using a non-detergent oil, your engine has probably accumulated large amounts of sludge. With the change to a detergent oil, the detergent additive loosens all of the deposits and very quickly overloads the oils ability to carry the deposits in suspension. The deposits will break away from engine surfaces and accumulate as a large mass at the pump strainer. When this happens, lubrication is interrupted and engine failure ensues. To avoid this, drain the detergent oil after only a few hours of operation—or sooner if coloration or appearance indicate fouling. Then refill with fresh oil, run 1,500 miles, change to fresh oil again, and follow our recommended oil change interval.

DIRT

Another reason to change engine oil frequently is to eliminate the formation of large quantities of dirt within the oil. Dirt can get into the engine in numerous ways. Inefficient or loose air filters allow passage of dirt through the carburetor and may be the single largest source of such violation. In addition, leaking gaskets, fouled fuel filters, loose oil filler caps, and use of filthy tools when servicing are all sources of dirt.

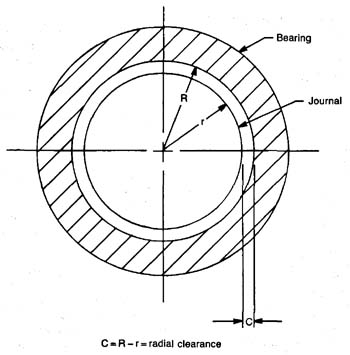

Fig. 3: C = A - r = radial clearance

To illustrate how important it is to keep dirt particles out of the engine, let’s take a look at bearing design and, in particular, bearing clearances (Fig. 3). Radial clearance (C) is equal to the bearing bore radius (R) minus the journal radius (r), as shown. Radial bearing clearance in new engines is of the order 0.0015 inches and smaller. That is a very small distance indeed. Any dirt particle 0.0015 or smaller that manages to wedge between the journal and bearing could scratch these surfaces, causing wear and decreased bearing and journal life. That is the reason engine oil must be kept as free of dirt as possible. Radial clearance increases with engine age, so it is more important to maintain a schedule of frequent oil changes while the engine is young and clearances are tight. Along with frequent oil changes, another way to keep oil relatively dirt-free is to frequently change the oil filter.

OIL FILTERS

All automotive engines have oil filters that remove, for a time, particles of dirt less than 1 micron (0.000034 inches) in size from the engine oil. Eventually, all oil filters become clogged and must be removed and replaced. There are two main types of oil filters: by pass and full flow.

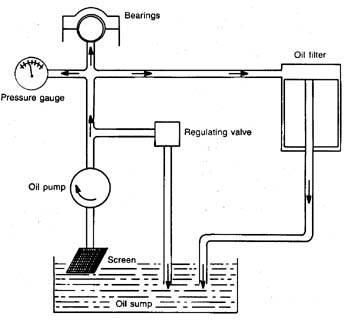

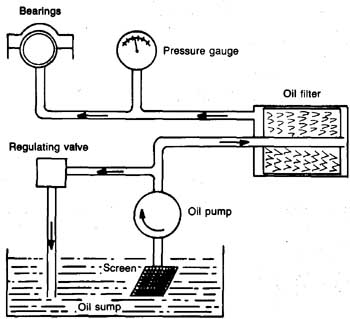

In bypass filtering (Fig. 4) most of the oil flow (about 90%) goes from the oil pump to the engine bearings. A much smaller quantity (about 10%) will bypass the bearings and flow through the oil filter. With this method, the oil filter material can be made dense enough to filter dirt particles down to 1 micron in size. However, not all of the oil is adequately filtered because of the bypass.

Fig. 4. Bypass lube oil system.

With full-flow filtering (Fig. 5) 100% of the oil is pumped through the oil filter for very efficient filtering. The one drawback to full-flow filtering is that the filter medium must be less dense to allow full oil flow without excessive pump pressure. This arrangement will allow small dirt particles to pass through the oil filter and back into the engine. These particles can be several microns in size. If this type of filter should become clogged, a relief valve will allow oil flow to bypass the filter.

Fig. 5. Full flow lube oil system.

Abrasive dirt particles in the engine oil can cause wear of the cylinder, piston rings, and bearings. That is why it is imperative that engine oil be kept clean. The filtering medium in the oil filter that removes these particles is made of cotton, paper, synthetic fibers, or cellulose. One might think that a constant change of filtering medium would be an ideal way to keep the oil clean. However, it is generally recognized that filtering also removes some of the beneficial additives from the engine oil, so the extent of filtering is questionable. Our recommendation is to change the oil filter at every recommended oil change (every 3,000 miles) and use the type (bypass or full-flow) specified by the manufacturer.

Engine oil must perform many jobs. It must reduce friction and resultant wear, keep the engine clean and free of oxidation and corrosion, act as a coolant, etc. It must do its job at high pressure and both high and low temperatures, and in an atmosphere polluted with dust, dirt, water, and contaminants caused by the combustion process. Oil is made up of many things to do many jobs, so pick a good one for many happy driving miles.

SUMMARY OF RECOMMENDATIONS

• Use a national brand multiviscosity (multigrade) engine oil. 10-W30 or 10-W40 works for most conditions. Consider using a 5-W20 multigrade engine oil for cold- weather driving, typically below 0 degrees Fahrenheit.

• Use an oil of performance classification SF.

• Always use detergent-type engine oils.

• Change the engine oil and filter at the same time—every 3,000 miles or sooner, especially with turbocharged cars that operate at higher temperatures, and for 4-cylinder cars that work harder than 6- or 8-cylinder cars.

MECHANIC’S TIPS

• Clean the oil pan every 2 years or 25,000 miles. At that time inspect the oil pump screen and clean or repair as required. Also inspect the bearings at this time.

• Drive at slow speeds and with light loads for at least the first 500 miles with a new car. The gray cast iron in the cylinders builds up a hard, glazed surface when under sliding friction. This glazing provides excellent wear resistance, and slow driving and light loads will facilitate the formation of this protective coating.

• Don’t use supplementary oil additives for normal driving. The oil manufacturer takes great precaution to include all the necessary additives and in the correct amounts and proportions. Considering our recommended oil change interval of 3,000 miles, buying cans of additive to supplement the oil is a waste of money. Exceptions: operation in an excessive idle mode or dusty environment.

• Check the oil level at least once a week or at every fuel-up.

• If your car is to be serviced by a mechanic, consider combining oil and filter changes with other service to save time and money.

• Never overfill the crankcase when adding or changing oil. High oil levels can become diluted with gasoline and become thin enough to pass by the piston rings and burn in the cylinder, resulting in oil consumption. If the oil smells like gas,

• change it and the filter. High oil level can also rob the engine of horsepower by dragging against crankshaft counter-weights, and may also cause main engine seals to leak or blow out. Also, high oil level may be picked up by the crankcase venting system and end up in the air filter or carburetor, which could ruin the air cleaner element or clog small carburetor passages.

• Use quality engine oil and filters; bargain products almost never save you money in the long run.

• Never race the engine when starting up; allow oil pump to build pressure and circulate oil to all high friction areas. Racing an engine only improves the chance of developing a “knock” or noise in your car, and once you have a knock, it will cost you money to get rid of it.

• Consider installing an engine oil cooler if you plan to do much heavy hauling or trailer towing.

• Keeping your car tuned up will help prevent the engine oil from being diluted with gasoline.

• If you change the oil yourself, always warm the engine to operating temperature first, then change the oil. This will help prevent the suspended dirt and deposits in the oil from clinging to the sides of the oil pan and contaminating the fresh oil. If you don’t want to change the oil yourself, have your mechanic do it or take the car to a quick-change oil center. Most of these oil changes and lube businesses promise a 15-minute completion time. Just make sure they use the type of oil we recommend.

• Combine car trips to save on gasoline and to make sure your engine warms to operating temperature. Driving on short trips for only a few miles will not rid the engine of harmful water vapor. Driving more miles will heat the engine to operating temperature, evaporate the water in the crankcase, and allow the vapor to be cleared by the ventilating system. Plan to drive at least 3 to 6 miles at a time in the summer and 10 to 14 miles in the winter for proper engine warm-up.

• Change the oil more frequently than the 3,000 mile recommendation if you do a lot of short-trip driving.

Prev: Philosophy of Car Care Next: Grease

Lubrication

Home top

of page