Now we present guidelines for the techniques you will need to build the projects in this guide, as well as basic information on tools, materials, hardware, spans and loads, joints, and reinforcing.

A description of wood and wood products can be only an introduction to their rich variety of tone, color, working and finishing characteristics, grain patterns and variations, defects, strengths, and vulnerabilities. The best education, and the most enjoyable one, is in the lumberyard itself. There you can see your choices, select just the material you want, and learn a great deal in the process. Ask questions, explore, take stock out of the racks and examine it for defects and special beauty. The guidelines below give you a starting point—the best part of learning about wood is left for you.

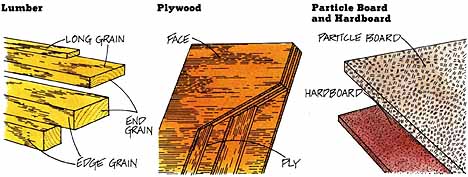

Lumber

— Of all wood products, lumber has the greatest rigidity and strength. Hardwoods, such as birch, oak, and cherry, are stronger and more durable than softwoods—fir and pine, for example.

— Lumber is sold in stock dimensions of thickness, width, and length, which means you can buy just the amount you need, plus a little extra for error. If you design your project using stock sizes, you can arrange it so the only milling required will be crosscutting the parts to length. At the lumberyard, you’ll ask for lumber by nominal dimensions—1 by 4 or 2 by 2, for instance. But remember that, as sold, lumber has been surfaced to standard finish dimensions, which are smaller. In designing your project, use the actual sizes.

— Softwoods in general are easy to work, and usually you need to pre-drill only for screws, not for nails. Hardwoods need to be pre-drilled for both nails and screws.

— For gluing and fastening, face grain and edge grain afford the most strength, end grain the least.

Plywood

— Plywood is made of layers (plies) of wood glued together with their grains running in alternating directions. Plywood faces may be made of either hardwood or softwood veneer.

— Plywood is typically sold in 4 by 8 sheets, which gives you great range in designing the size and shape of your project. But buying in sheets means you’ll have to do more cutting—both ripping and cross cutting. Plywood ranges in thickness from 1/8 inch to 1-1/8 inches; for projects like those in this guide, the most commonly used thicknesses are 1/4 inch, 1/2 inch, and 3/4 inch.

— Most plywoods are made up with interior plies of softwood, so you don’t need pilot holes for nails, but you’ll need them for screws.

— Plywood is a fine building material; but to give a plywood project its best appearance, you’ll want to conceal exposed plies with edging. Take care in sanding any plywood, so that you don’t sand right through the face; hardwood surface veneers, in particular, are thin.

Particle Board and Hardboard

— Particle board and hardboard are made of wood chips or fibers glued together in random directions and compressed.

— These materials are less expensive than lumber and plywood. They are sold in 4 by 8 sheets. Hardboard comes in 1/8-inch and 1/4-inch thicknesses. Particle board comes in thicknesses from 1/4 inch to 3/4 inch; it is also available in a range of standard shelving widths, sometimes with a finished front edge. Particle board comes in different grades. Underlayment grade has a rough surface and gives a coarse appearance. Industrial grade, by contrast, is dense and smooth, and takes paint well; it is a better product for the projects in this guide.

— Because hardboard and particle board have no continuous grain direction, they’re tricky to fasten well. The binding glues are abrasive and are apt to dull your cutting tools. You’ll need to pre-drill particle board for screws but not for nails; you may be able to fasten hardboard without pre-drilling, depending on whether it’s been tempered.

Previous: Racks

Next: Spans and Loads

ALL ARTICLES in this Guide:

DIY and Custom-Made Storage Solutions: Components You Can Build for Home, Office ... as a Hobby or for Sale (Profit, earn Income)